Alliance Laundry Systems BU170S Service Manual Page 48

- Page / 120

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

46

70422201R1

Adjustments

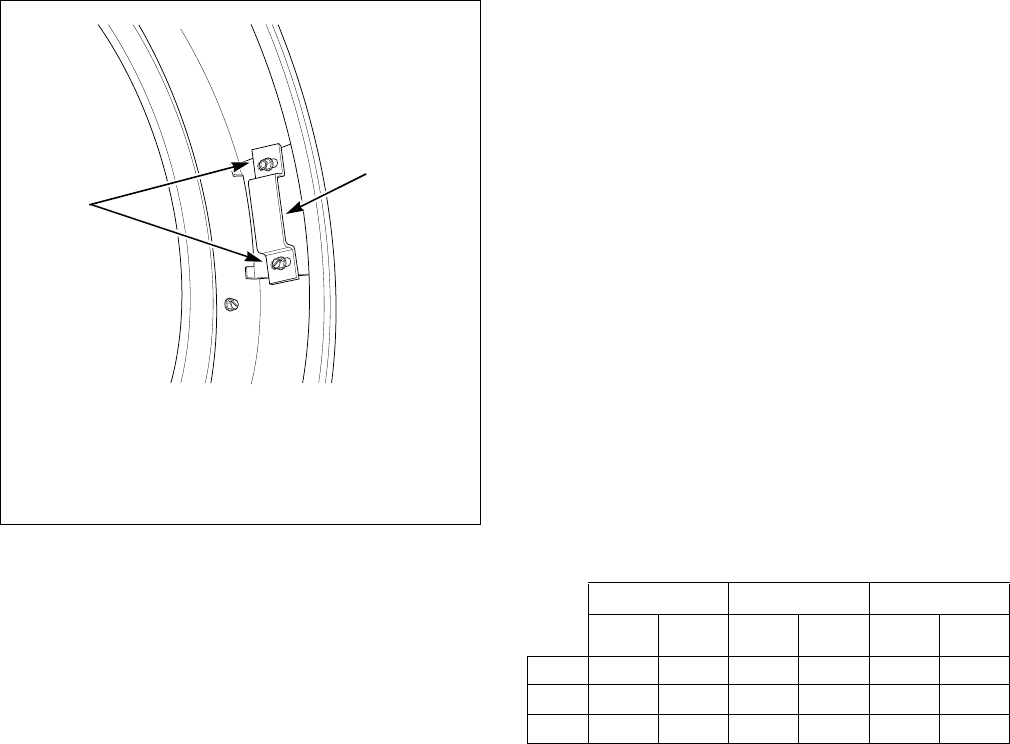

29.Loading Door Strike (200 Pound

Models)

The loading door strike must be adjusted to have

sufficient tension to hold loading door closed against

force of load tumbling against it. Proper adjustment is

when 8-15 pounds (35.6-66.7 N) pull is required to

open door.

If adjustment is required, refer to Figure 5 and proceed

as follows:

To adjust, open door, loosen adjustment screws and

position strike for desired magnet engagement.

Retighten screws.

Figure 5

30.Belt Drive

The drive assemblies consist of motors, belts, eyebolts

and a step pulley.

The pulley diameters are sized to produce a cylinder

speed of 37-39 RPM for 120 pound models or

29-31 RPM for 170 and 200 pound models.

The step pulley assembly is used for speed reduction

as well as a means of adjusting belt tension. The pulley

mounting plate is attached to the cabinet. The frame

mounting plate has vertically slotted holes allowing up

and down movement of the step pulley mounting plate

for belt adjustment.

Adjust the belt tension as follows:

1. Disconnect electrical power to the tumble dryer

before attempting any adjustments to the drive

assembly.

2. Loosen pulley mounting plate bolts.

3. Loosen the upper nut on the final drive eyebolt.

4. Rotate the lower nut of the final drive eyebolt

clockwise until proper belt tension is achieved.

5. Rotate upper nut clockwise against the lower nut

in order to lock it into place.

6. Tighten pulley mounting plate bolts. Recheck

belt tension.

7. If necessary, adjust the drive motor belt tension

eyebolt using a similar procedure.

8. Adjust blower belt tension on 120 pound

50 Hertz tumble dryers and all 170 pound tumble

dryers using a similar procedure.

NOTE: Proper tensions for new belts are measured

with a Belt Tension Gauge:

Using a Belt Tension Gauge, the motor belt

deflection should be 0.31 inch at five pounds

pressure, and final drive belt deflection should be

0.25 inch at five pounds pressure.

Belts should not slip or make any noise when starting

up under normal load.

TMB2359N

1 Door Strike

2 Adjustment Screws

1

2

Drive Motor Final Drive Blower

Initial

After

Run-in Initial

After

Run-in Initial

After

Run-in

120 60-70 45-55 70-80 55-65 60-70 50-55

170 60-70 45-55 70-80 55-65 75-80 60-65

200 60-70 45-55 70-80 55-65 65-70 55-60

Table 1

- STRIAL TUMBLE DRYERS 1

- Table of 3

- Contents 3

- 70422101R1 4

- Section 1 5

- Safety Information 5

- Safety Warnings and Decals 7

- Tumblers 7

- Section 2 8

- Introduction 8

- Customer Service 10

- Serial Plate Location 10

- How a Tumble Dryer Works 11

- Operation 12

- Temperature Sensor 13

- Modes of Operation 14

- Section 3 15

- Troubleshooting 15

- 1. Motor Does Not Start 16

- 4. Motor Does Not Stop 19

- 6. No Heat Condition 21

- 7. Gas Burner Does Not Ignite 22

- 12.Clothes Do Not Dry 27

- 13.Tumble Dryer Overheating 28

- TMB2357S 34

- TMB2319S 35

- TMB2368S 36

- 21.Cylinder Is “Stained” 39

- Section 4 40

- Call the fire department 41

- TMB2199N 44

- SUPPRESSION 45

- Section 5 46

- Adjustments 46

- 27.Airflow Switch 47

- Pound Models) 47

- 30.Belt Drive 48

- 31.Cylinder Clearance 49

- TMB1786S 50

- 32.Drive Belt Tension 51

- 33.Fan Belt Tension 52

- Section 6 53

- 34.Control Has No Display 54

- 36.Motor Will Not Start/Run 58

- 37.Unit Will Not Heat – Gas 60

- 38.Error Codes 63

- Section 7 64

- 39.Control Has No Display 65

- 40.Door Open Indicator 67

- 41.Motor Will Not Start/Run 70

- 43.Error Codes 75

- Section 8 76

- Is there line voltage 77

- TMB2387S 79

- 45.No Drive Motor Rotation 80

- LED OPL Error Display: E Cab 83

- Is there 24 volts AC 85

- 48.Airflow Errors 87

- LED OPL Error Display: E FnCs 89

- 50.Close Door Indication 91

- 51.Moisture Sensor Error 93

- Figure 9 95

- Figure 10 96

- (Refer to Figure 11) 97

- Figure 12 98

- Machine Basket Removed 99

- Figure 13 100

- 58.Fan Motor Contactor Error 101

- TMB2383S 102

- 59.Rotation Sensor Error 103

- Rotation Sensor Error 104

- 60.Shorted or Open Thermistor 105

- Shorted or Open Thermistor 106

- SEE VOLTAGE 107

- OPTION DIAGRAM 107

- PROGRAMMING DIP SWITCHES 108

- (SEE INSTALLATION MANUAL 108

- FOR SWITCH DETAILS.) 108

- 63.Electronic Control Testing 109

- 70422201R1 110

- Diagnostic Test Descriptions 111

- Production Test Cycle 116

- 64.Diagnostic Testing 117

- Diagnostic Menu 117

- Test Menu 117

- Test Cycle Chart 118

- Inputs Outputs Menu 119

- Alarms Menus 120

- Machine ID Menu 120

(23 pages)

(23 pages) (136 pages)

(136 pages) (74 pages)

(74 pages)

Comments to this Manuals